Plastic cutters are used for commercial, industrial, and consumer applications. Manual plastic cutters are best for small-scale plastic-cutting operations, while automated plastic-cutting equipment works well for larger operations. Sheet and tube cutters are the two most popular kinds of plastic cutters. Read More…

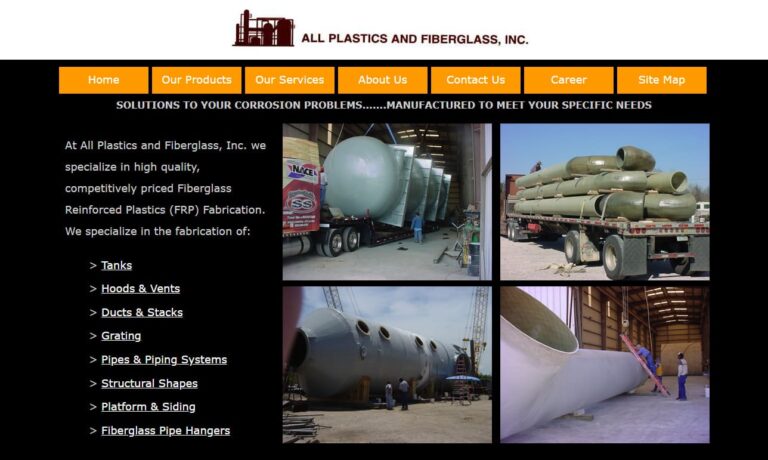

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

At Creative Design and Machining, we specialize in delivering high-quality plastic fabrication solutions that meet the unique needs of our customers across a wide range of industries. We take pride in combining innovative design capabilities with advanced machining techniques to produce components that are both functional and reliable.

More Plastic Cutter Companies

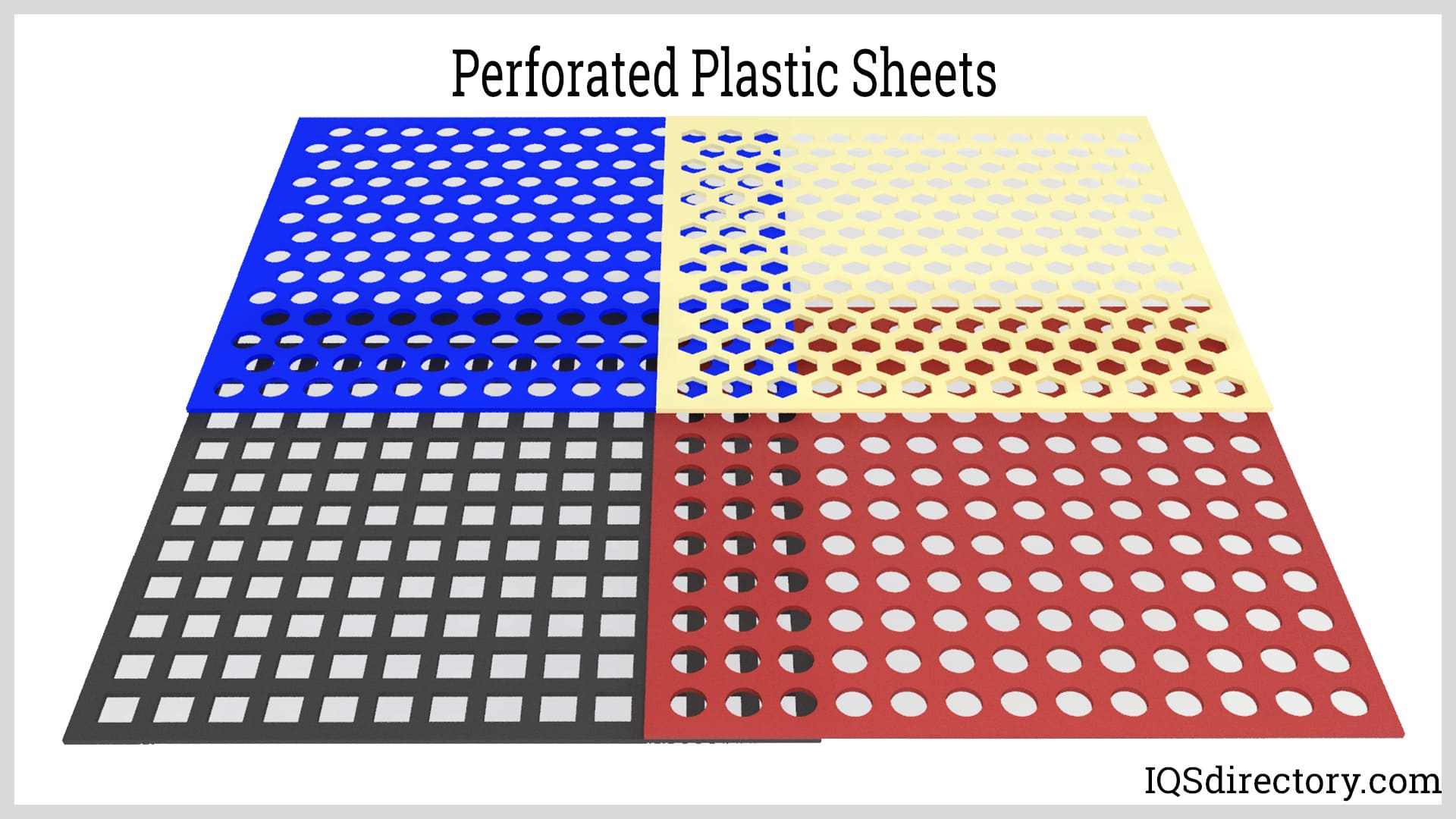

Sheet cutters are specialized cutting tools equipped with high-precision blades and ergonomic handles—typically constructed from durable plastic or rubber—to enable users to accurately trim, slice, or shape plastic sheets. These plastic sheet cutters are essential for industries requiring clean, reliable cuts in acrylic, polycarbonate, PVC, PETG, and other thermoplastic materials. By allowing operators to achieve smooth edges and precise dimensions, sheet cutters play a crucial role in fabrication, prototyping, and installation processes within the sign-making, construction, packaging, and manufacturing sectors.

In addition to sheet cutters, plastic tube cutters are indispensable hand tools engineered for efficient, clean cuts in plastic piping and pipefitting applications. Plastic tube cutters are explicitly designed to outperform conventional tools such as hacksaws by delivering fast, square cuts on a wide range of piping materials—such as PVC, CPVC, PEX, polyethylene, and polybutylene—without producing excessive burrs or deformation. This makes them the preferred choice for plumbers, HVAC technicians, irrigation specialists, and industrial maintenance teams who require reliability, safety, and repeatable results in every cut.

Types of Plastic Cutting Methods

Selecting the optimal plastic cutting method is vital for achieving superior results in plastic fabrication and machining. Advanced cutting techniques—including routing, trimming, sawing, laser cutting, die cutting, and waterjet cutting—are frequently employed when converting plastic sheets, rods, and tubes into finished components. Each plastic cutting method is tailored to specific material properties, part geometries, and production volumes, and the right choice can dramatically influence efficiency, surface finish, and dimensional tolerances.

Routing and trimming, in particular, are two of the most common machining techniques for transforming plastic parts into finished goods. The secret to successful plastics machining lies in aligning cutter design—such as the blade profile, rake angle, and flute geometry—with the unique machining properties of the chosen plastic substrate. While the relationship between the cutter and the polymer's mechanical and thermal characteristics is paramount, additional factors such as CNC programming, coding strategies, fixturing methods, and dust/chip extraction systems also play significant roles in achieving consistent, high-quality results.

Routing

Routing is a versatile plastic cutting method that employs high-speed rotary cutting tools (router bits) to remove material in complex shapes, profiles, and contours. When routing polymers, it is essential to maintain fast feed rates and high spindle speeds to produce smooth, high-quality finishes without melting, burning, or chipping the work surface. Routing is widely used for fabricating intricate panels, signs, enclosures, and custom components from acrylic, polycarbonate, UHMW, and ABS, among others.

One of the critical challenges in plastic routing is preventing the plastic chips (or swarf) generated during cutting from rewelding or fusing back onto the finished edge—especially with softer plastics prone to heat buildup. If chips reweld, the resulting edge finish can be rough, uneven, or marred by surface defects, compromising both aesthetics and functional fit. The key to effective plastics machining is to avoid this rewelding while maintaining high feed rates and achieving a fine, polished edge finish.

To minimize the risk of chip rewelding, it is important to keep chips cool and evacuate them efficiently during the routing process. However, this is not always feasible due to CNC programming limitations, especially when processing tight radii, intricate corners, or complex part geometries. Most CNC routers have acceleration, deceleration, and curve speed restrictions that can cause the tool to pause or slow down, increasing the risk of heat buildup and chip adhesion. When possible, avoid dead stops or prolonged tool dwell times—particularly at outside corners—since these can lead to loitering and inferior cut quality.

Correct Spoil Board Technique

Proper spoil board technique is fundamental for achieving clean, accurate cuts and extending tool life in plastic routing operations. The spoil board—typically made from MDF, plywood, or sacrificial plastic—supports the workpiece, prevents breakthrough damage, and helps maintain vacuum hold-down integrity during machining.

Router bits may linger in the entry "dip" of an inside cut, especially if the tool is not spiral-fluted or sheared. When this happens, the bit can repeatedly contact the cut surface, impeding chip evacuation and increasing the risk of chip rewelding. One proven solution is the “ramp in” technique, where the tool gradually plunges into the material as it moves forward along the toolpath. This minimizes chip accumulation and reduces the thermal load on both the tool and the plastic workpiece.

Although ramped-entry programming may lengthen the routing path and cycle time, it is often economically justified by improved cut quality, reduced risk of tool breakage, and longer tool service life. For high-volume or precision applications, spoil board maintenance—such as regular resurfacing or replacement—is also essential for maintaining consistent results.

Fixturing

Reliable fixturing is a cornerstone of successful plastic cutting and machining operations. Fixturing refers to the methods and devices used to securely hold plastic sheets, rods, or tubes during cutting, routing, or trimming. Proper fixturing prevents vibration, shifting, or lifting of the workpiece, all of which can negatively impact edge finish, dimensional accuracy, and tool life.

Advanced fixturing systems may include vacuum tables, mechanical clamps, edge stops, or custom jigs designed to match the part geometry. For thin or flexible plastics, vacuum hold-down is often preferred as it provides uniform support across the entire surface, minimizing chatter and deflection. For thicker or formed plastics, mechanical clamps or hybrid systems may be necessary to ensure stability.

Inadequate or unstable fixturing can lead to a range of problems, including rough edges, tool breakage, excessive wear, or even part rejection. By investing in robust fixturing and regularly checking for wear or misalignment, manufacturers and fabricators can ensure the highest levels of productivity, repeatability, and finished-part quality.

Cutting Soft Plastics

Soft plastics—including materials like polyethylene (PE), polypropylene (PP), and flexible PVC—are prized for their impact resistance, flexibility, and ease of machining. When cutting soft plastics, the large, continuous chips produced during routing or sawing are quickly expelled from the path of the cutting tool. This efficient chip evacuation significantly reduces the risk of material build-up on the tool and prevents melting or burning, even at high feed rates.

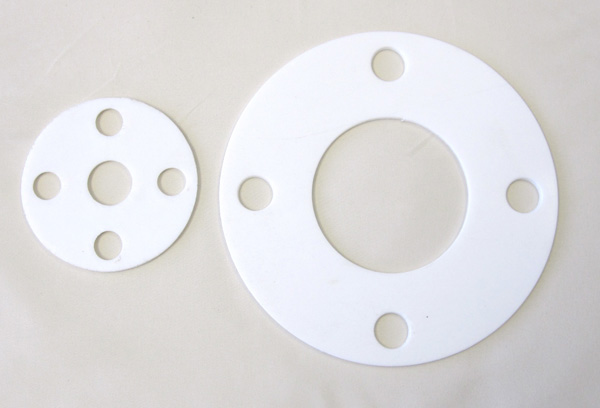

Unlike harder thermoplastics, soft plastics rarely exhibit edge burring or fuzzing, resulting in clean, smooth edges with minimal post-processing required. The generous tool rake angles used for soft plastics facilitate easy chip separation, reduce cutting forces, and allow for rapid material removal while minimizing workpiece movement. These properties make soft plastics ideal for high-speed production of gaskets, seals, liners, packaging inserts, and flexible tubing components.

Best Practices for Cutting Soft Plastics

- Use sharp, high-clearance blades or router bits specifically designed for soft polymers.

- Maintain high feed rates and moderate spindle speeds to optimize surface finish and prevent heat buildup.

- Employ efficient dust/chip extraction systems to keep the workspace clean and safe.

- Regularly inspect cutting tools for signs of dulling or resin build-up, and replace as needed.

- Select appropriate fixturing and support to prevent flexing or vibration during cutting.

Cutting Hard Plastics

Hard plastics—such as acrylic (PMMA), polycarbonate (PC), acetal (POM), and nylon—present unique challenges for cutting, machining, and finishing. These engineering plastics are valued for their mechanical strength, optical clarity, and dimensional stability, which makes them ideal for structural, optical, and precision parts.

When cutting hard plastics, the waste material typically takes the form of tiny shards, crystalline particles, or fine dust. Unlike the continuous chips produced in soft plastic cutting, hard plastic machining involves fracturing the material into small, uniform fragments. This behavior is due to the brittle nature and higher melting points of engineering plastics, which require more controlled cutting parameters to avoid cracking, crazing, or surface chipping.

Best Practices for Cutting Hard Plastics

- Use fine-tooth saw blades, carbide-tipped router bits, or diamond-impregnated tools for optimal edge quality.

- Employ moderate feed rates and higher spindle speeds to reduce heat and prevent edge chipping.

- Utilize compressed air or vacuum extraction to efficiently remove dust and chips from the cutting area.

- Implement gradual entry and exit cuts to minimize internal stresses and potential for cracking.

- Consider coolant or lubricant application for thick or heat-sensitive plastics to further enhance finish and tool life.

By carefully selecting cutting tools and optimizing machine parameters, fabricators can achieve superior results when processing hard plastics, ensuring tight tolerances, smooth edges, and high-quality finished parts for demanding applications in industries such as aerospace, automotive, medical, and electronics manufacturing.

Evaluating Plastic Cutting Tools: What Should Buyers Consider?

Choosing the right plastic cutting tool—whether it is a manual sheet cutter, a ratcheting tube cutter, or a CNC routing bit—can have a significant impact on efficiency, safety, and finished part quality. Here are key decision factors to guide your selection process:

- Material Compatibility: Ensure the tool is engineered for the specific type and thickness of plastic you need to cut. Not all blades or cutters are suitable for every polymer.

- Precision and Finish: Evaluate the tool’s ability to deliver clean, burr-free edges with minimal secondary processing, which is essential for parts used in visual, medical, or high-precision applications.

- Ergonomics and User Comfort: For manual cutters, prioritize designs with ergonomic handles, lightweight construction, and slip-resistant grips to reduce operator fatigue during repetitive tasks.

- Cutting Capacity and Versatility: Consider tools that can accommodate a range of material thicknesses, diameters, and shapes—especially if your operations require frequent material changes.

- Durability and Maintenance: Look for cutters made from high-quality steel, carbide, or diamond-tipped materials for extended tool life and lower replacement costs.

- Safety Features: Opt for tools with retractable blades, blade guards, or locking mechanisms to minimize the risk of accidental injury.

- Production Volume: For high-volume or automated environments, evaluate the suitability of CNC routers, laser cutters, or waterjet systems, which deliver speed, consistency, and repeatability.

Understanding your unique application requirements, budget constraints, and desired output quality will help you narrow down the most suitable plastic cutting tools—whether for one-off projects, prototyping, or mass production.

Common Applications and Use Cases for Plastic Cutters

Plastic cutters and cutting tools are essential across a broad spectrum of industries and use cases. Whether you are an industrial manufacturer, a contractor, a DIY enthusiast, or a professional fabricator, the right plastic cutting equipment can make all the difference in achieving high-quality results efficiently. Here are some common applications:

- Signage and Display Fabrication: Sheet cutters and CNC routers enable precise cutting of acrylic, polycarbonate, and PETG for illuminated signs, retail displays, and exhibition graphics.

- Plumbing and HVAC Installation: Plastic tube cutters are used for trimming PVC, CPVC, and PEX pipes to length, ensuring leak-free joints and smooth connections.

- Packaging and Prototyping: Die cutting and laser cutting tools convert plastic sheets into custom packaging inserts, blister packs, and prototype enclosures for new product launches.

- Automotive and Aerospace Parts: Advanced CNC cutting equipment is used to machine engineering plastics into bushings, brackets, covers, and panels for vehicles and aircraft.

- Medical Device Manufacturing: Precision plastic cutters are essential for producing diagnostic housings, surgical trays, and disposable components from biocompatible polymers.

- DIY and Crafting: Handheld plastic cutters and hobby knives make it easy to create models, templates, stencils, and custom art from lightweight plastic sheets and films.

Benefits of Using Specialized Plastic Cutters

Why should you invest in purpose-built plastic cutting tools rather than relying on generic equipment? The benefits are substantial:

- Cleaner Cuts: Specialized blades and cutters deliver smooth, square edges, minimizing the need for labor-intensive finishing or deburring.

- Increased Productivity: Tools engineered for plastics operate faster and require less operator effort, boosting throughput for both manual and automated workflows.

- Reduced Waste: Precision cutting reduces material loss, helping you maximize yield from every sheet or tube.

- Enhanced Safety: Ergonomic handles and built-in safety features reduce the risk of injuries compared to makeshift solutions.

- Consistent Results: Repeatable, accurate cuts ensure every part meets specification, reducing scrap and rework.

- Extended Tool Life: Plastics-specific cutters are designed to minimize wear and resist gumming, lowering long-term tooling costs.

Choosing the Correct Plastic Cutter Manufacturer

To ensure the most productive outcome when purchasing plastic cutters from a plastic cutter manufacturer, it is important to compare several companies using our directory of plastic cutter manufacturers. Each plastic cutter manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each plastic cutter business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic cutter businesses with the same form.

Frequently Asked Questions About Plastic Cutters and Cutting Methods

What types of plastics can be cut with standard plastic cutters?

Most standard plastic cutters are suitable for common thermoplastics such as acrylic, polycarbonate, PVC, CPVC, PEX, polyethylene, and polypropylene. For harder or thicker engineering plastics (e.g., acetal, nylon, or fiberglass-reinforced composites), specialized blades or power tools may be necessary to achieve clean, accurate cuts.

How do I maintain and extend the life of my plastic cutting tools?

Regularly clean cutting blades after use to remove resin buildup, dust, and chips. Sharpen or replace blades as soon as you notice dullness or increased cutting resistance. Lubricate moving parts on manual cutters and store tools in a dry, safe location to prevent corrosion or mechanical wear.

Should I use a manual or powered plastic cutter?

Manual plastic cutters are ideal for small-scale jobs, tight spaces, or delicate work where control is paramount. Powered options such as electric shears, rotary cutters, or CNC routers are recommended for high-volume production, thick materials, or intricate shapes that require speed and precision.

What safety precautions should I follow when cutting plastics?

Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and dust masks. Secure your workpiece with reliable fixturing to prevent movement. Use sharp, well-maintained tools and follow manufacturer guidelines for operation. Ensure proper ventilation when working with plastics that may emit fumes or dust during cutting.

How do I choose the right blade or cutter geometry for my application?

Consider the plastic’s hardness, thickness, and desired edge quality. Use high-clearance, sharp blades for soft plastics to prevent melting and ensure clean separation. For hard plastics, select fine-tooth or carbide-tipped blades to minimize chipping and produce smooth, polished edges.

Conclusion: Advancing Your Plastic Cutting Operations

Whether you are fabricating complex assemblies for industrial use, installing piping in a new construction project, or crafting custom signage, choosing the right plastic cutting tools and methods is essential for achieving professional results. By understanding the properties of your materials, selecting appropriate cutting techniques, and investing in quality cutters from reputable manufacturers, you can enhance productivity, safety, and finished-part quality across any application.

As plastic fabrication technologies continue to evolve—including advancements in CNC routing, laser cutting, and automated fixturing systems—businesses and individuals have more options than ever to cut plastics efficiently and precisely. Stay informed of new developments, follow best practices, and rely on expert suppliers to meet all your plastic cutting needs—from sheet cutters and tube cutters to advanced CNC equipment.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services