Design Converting, Inc.

Design Converting, Inc.Request A Quote

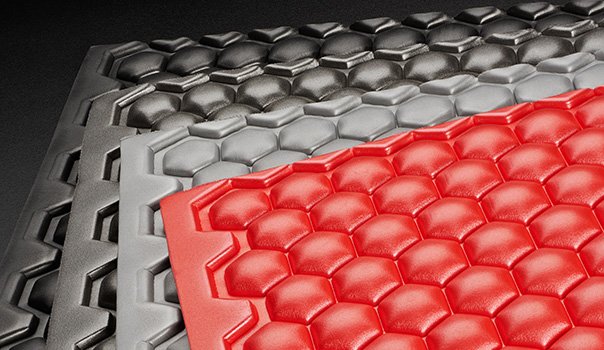

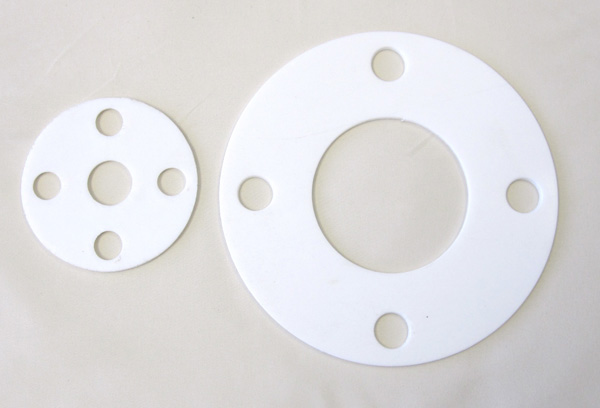

Grand Rapids, MI | 616-942-7780The mission of Design Converting, Inc. is clear cut: to be the choice supplier for plastic die cutting, foam die-cutting, rubber die-cutting, fabrication and secondary services to its valued customers. Offering further processes such as laminating, screen-printing and stamping, DCI has grown both in service capability and in customers since our formation in 1996. With a commitment to continual improvement and high standards, DCI holds an ISO 9001:2015 certification for its quality management system. As evidence of this commitment, our team at DCI works closely with our customers, from initial product consulting to engineering and design to final production, ensuring the finished product meets the specific characteristics and tolerances often required in die cut parts and components. Working with industries as varied as automotive, medical, consumer and OEMs, Design Converting has practical experience meeting a broad range of die cutting needs in plastics, foam and rubber. Manufacturing options include different types of adhesives or the option for no adhesive, as well as the willingness to work with less common materials. DCI aims to offer a cost effective option to its customers and strives to find the best solution on a job-specific basis rather than offering standard solutions, even if that means sourcing an unusual material for a custom need. Samples, prototypes and short production runs are also available to our customers as required. While providing creative solutions and unparalleled quality in terms of products and services, we hope to be a part of encouraging the trend of local manufacturing. DCI sees the opportunity for American manufacturers and small businesses to play a vital role in industry as the economy slowly picks up and business conditions begin to improve.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services