This type of machining is known as subtractive manufacturing. However, sometimes the machining does involve adding material, such as a coating. This type of machining is known as additive manufacturing. Read More…

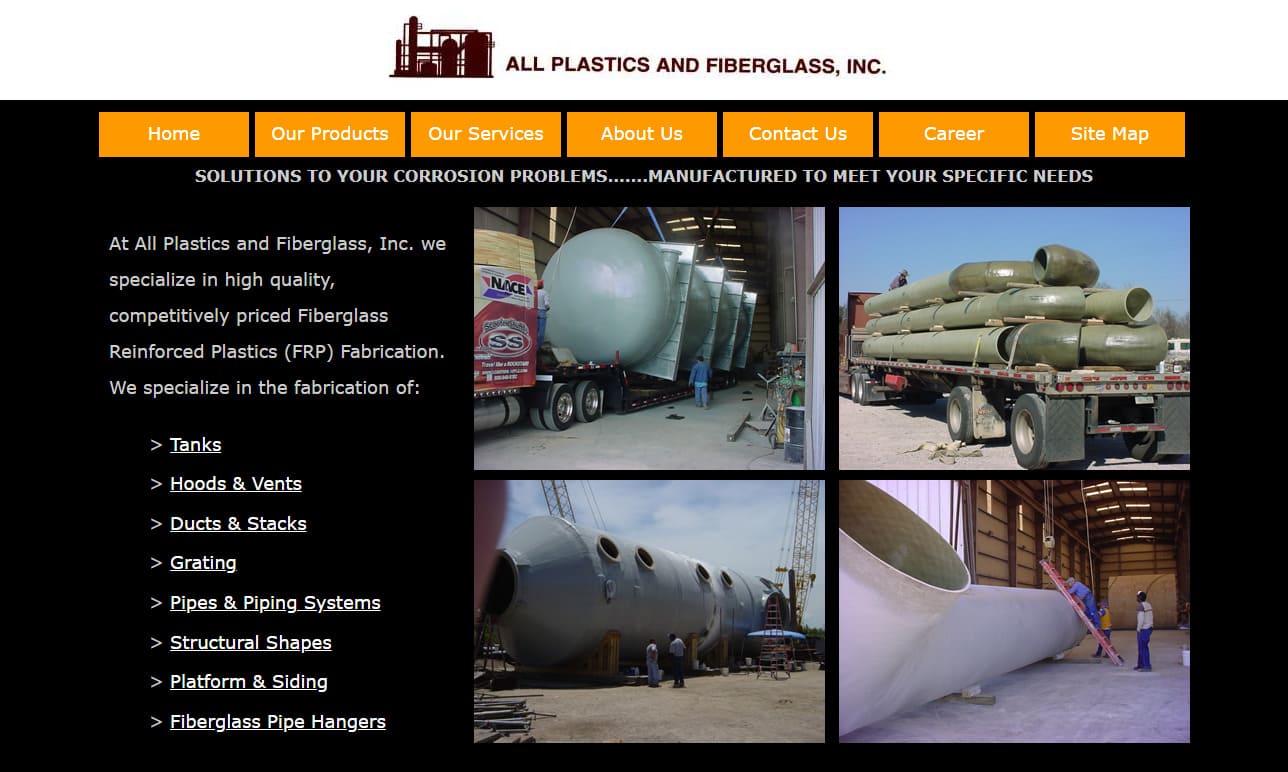

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Plastic Machining Companies

Some common types of plastic machining include: CNC plastic machining, drilling, milling and turning. Examples of others include: laser cutting, electro discharge machining (EDM) and waterjet cutting.

CNC Plastic Machining

Most plastic machining systems fall under the CNC machining category. CNC, computer numerical control, technology is that equipment and software that allows machinists to program systems. CNC technology makes machining faster, more precise, more efficient and less expensive.

Drilling

During drilling, machinists create or perfect holes in the workpiece. Usually, they use drill presses to do this, but sometimes they use mills or lathes. Drill presses feature a cutting mechanism that rotates rapidly as it descends on the plastic piece.

Milling

Milling involves rotating automated or semi-automated cutting tools around a workpiece. Plastic milling can be done completely independent of operators, saving manufacturers time and money.

Turning

Turning, sometimes called lathe turning, is essentially the opposite of milling. It involves using a lathe to turn a plastic workpiece as cutting tools move against it.

Some of the many industries that rely on plastic machining are: electronics, healthcare, instrumentation, construction, semiconductor, sports and recreation, food and beverage, appliance, automotive and aerospace.

To carry out their designs, machinists may use countless standard and custom plastic formulas. Among the most common are: PVC, PTFE, PEEK, ABS, acrylic, acetol, HDPE, LDPE and more. For those who are interested, most manufacturers also offer eco-friendly options. Because manufacturers can alter plastic properties before machining them, the possibilities with plastic machining are virtually endless.

While metal manufacturer is a more traditional process than plastic machining, plastic machining is rapidly outpacing it because of rising metal prices. On top of that, the switch to plastic machining tends to reduce waste, weight, the time and costs associated with design change, and operation costs in general. Don’t forget, when machinists save money, they can pass those savings along to their customers.

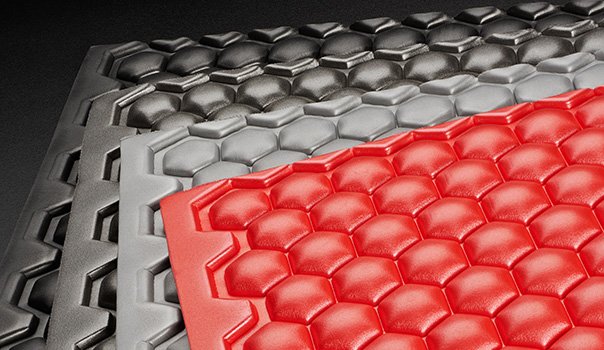

Die Cutting

Die Cutting Foam Fab

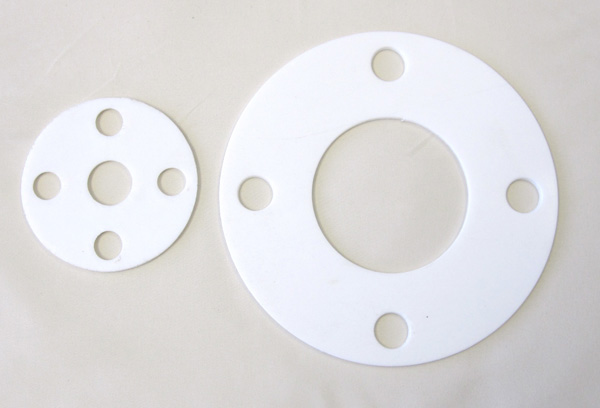

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services