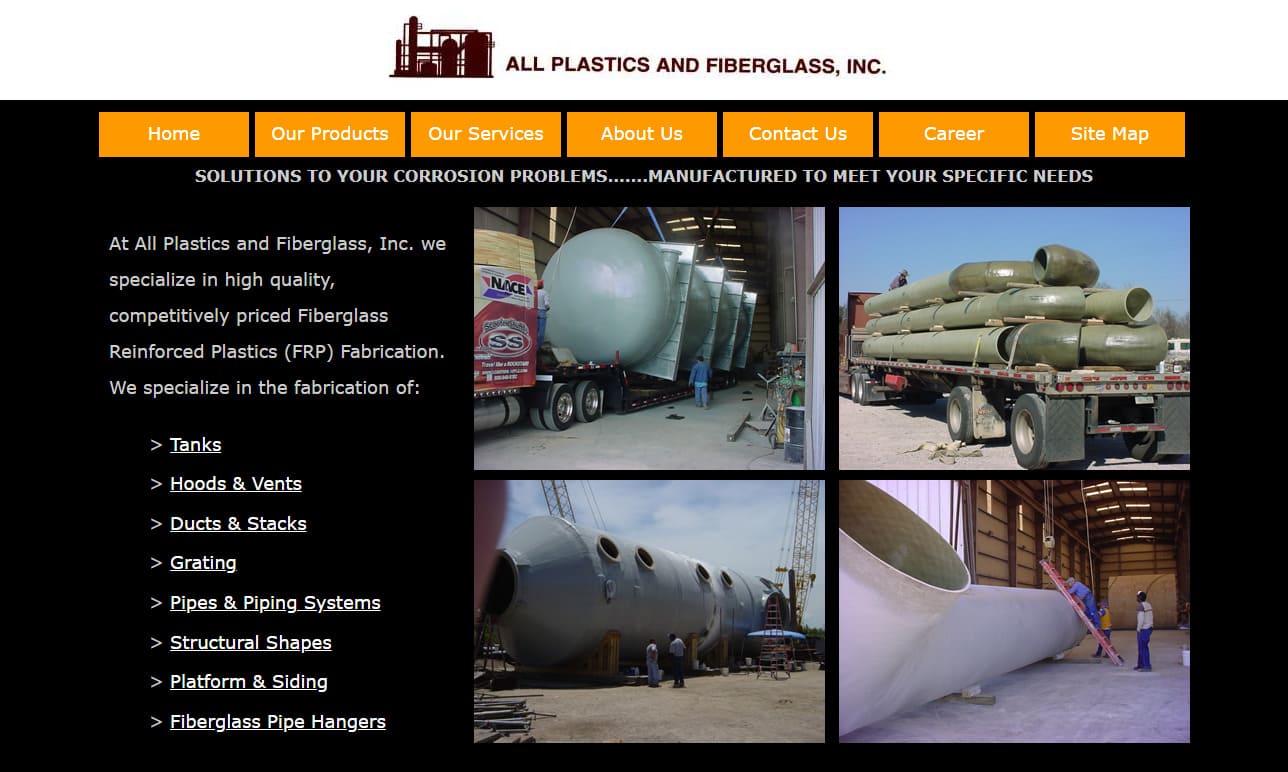

Just about every industry utilizes plastic fabrication at some point in their processes as plastic itself provides a solution to a wide range of needs. Read More…

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

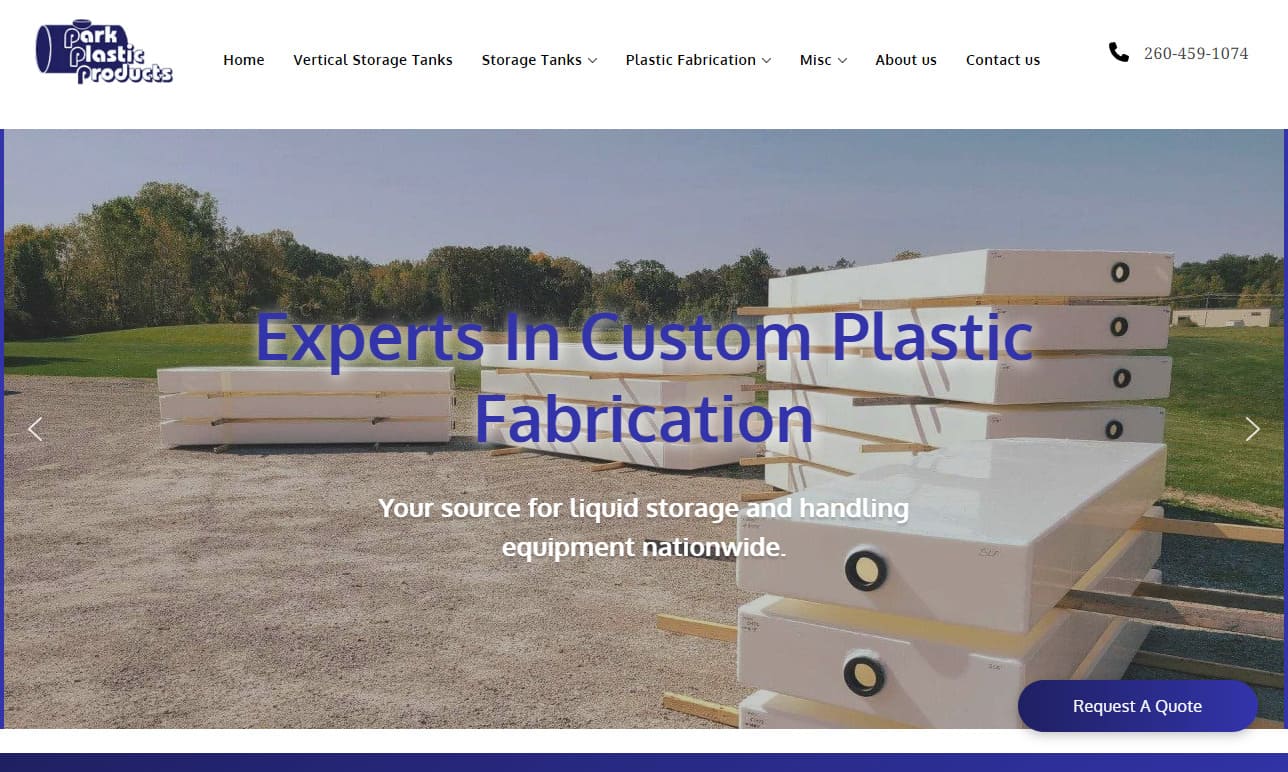

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Plastic Part Companies

The style in which it is fabricated allows for the plastic to become more advantageous within certain applications than others, so in order to receive the plastic parts that you need, you must first find a plastic fabricator that can listen to your exact needs and manufacture a product based on your unique specification and application requirements.

The overall process of manufacturing plastic parts is one that typically sees the plastic evolve from its raw form into the final product all within the house of one manufacturing company that specializes in creating that form of final plastic part. In other cases, some plastic parts manufacturers will take custom designs and create prototypes of these designs in order to receive approval before launching a full, large run manufacturing order.

This allows the manufacturer to create a product to display to the customer so that the customer can have an idea of what the final product will look like and can make any modifications or improvements before full production. It also allows the manufacturing team to modify the fabrication process to improve production speed, efficiency, and structural integrity of the product.

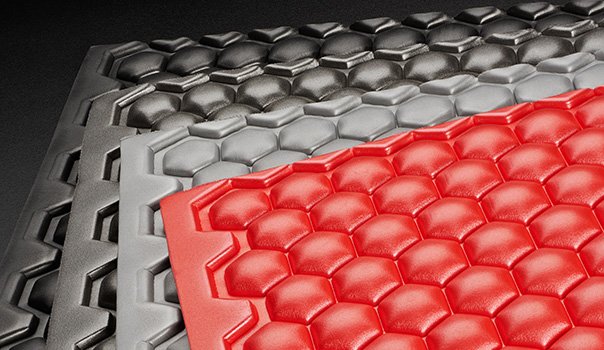

The plastic parts fabricating process can be utilized to make anything from children's toys to screws to unique, custom cases. As mentioned before, the plastic itself can be manipulated in order to create certain attractive physical properties such as added flexibility or strength, a different form of texture or even just a different color.

Whatever your application may be, consulting with a reputable plastic parts manufacturer is the best way to ensure that you receive a product that meets your expectations and application requirements. Be sure to look out for companies who offer prototyping services as this is a great way to "try it before you buy it," which can be a great tool especially when looking to mass-produce a certain type of item.

Die Cutting

Die Cutting Foam Fab

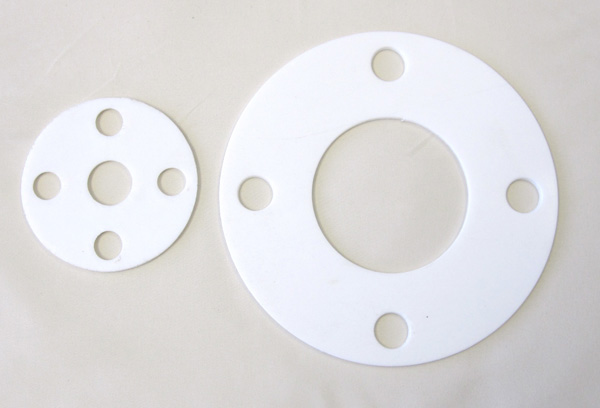

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services