Plastic manufacturing is the process of producing synthetic polymers, which are widely used in everyday life due to their versatility, durability, and low cost. In this article, we will explore the plastic manufacturing process, variations in the process, topics to consider regarding plastic manufacturing, and its benefits and applications. Read More…

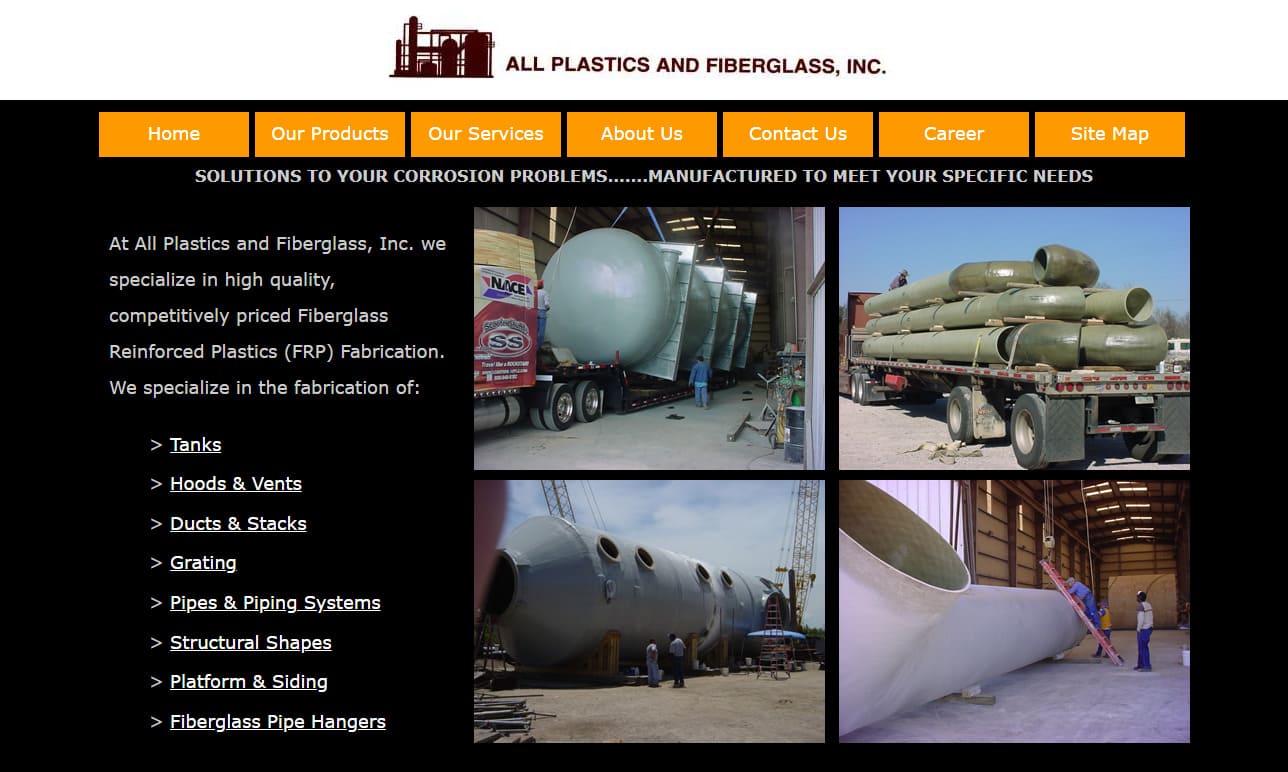

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Plastic Manufacturing Companies

The Process of Plastic Manufacturing

The plastic manufacturing process begins with the preparation of raw materials. The raw materials include resins, colorants, stabilizers, and additives. The materials are then melted and combined through a process called polymerization. This process creates a long chain of molecules known as a polymer. Once the polymer has been created, it is molded into its desired shape through various techniques such as injection molding, blow molding, or extrusion. Finally, the newly formed plastic product is cooled and finished.

Variations in the Plastic Manufacturing Process

The plastic manufacturing process can vary depending on the type of plastic being produced, as well as the intended application of the final product. Some of the more popular variations of the plastic manufacturing process are discussed below:

Extrusion

Extrusion is a process that involves melting the plastic and forcing it through a die to create a specific shape or form. This process is commonly used to create plastic tubing, sheets, and films.

Injection Molding

Injection molding involves melting plastic pellets and injecting them into a mold cavity, where they cool and solidify to form the desired shape. This process is commonly used to produce plastic parts for various products.

Blow Molding

Blow molding is a process where a hollow plastic tube, or "parison," is inflated with air to create a specific shape. This process is commonly used to produce plastic bottles, containers, and other hollow shapes.

Thermoforming

Thermoforming involves heating a sheet of plastic until it becomes pliable, then stretching or shaping it over a mold to create a specific shape. This process is commonly used to produce packaging materials and trays.

Rotational Molding

Rotational molding is a process where a hollow mold is filled with plastic resin, then rotated on two perpendicular axes until the plastic evenly coats the mold's interior. The mold is then cooled and removed to reveal the final product.

Considerations Regarding Plastic Manufacturing

While plastic manufacturing provides many benefits, it does present some topics to be addressed. One of the most significant issues with plastic manufacturing is the environmental impact. Plastic waste can take centuries to decompose, causing pollution and harming wildlife. Additionally, some plastics contain harmful chemicals that can pose a health hazard. The production of plastics also requires significant amounts of energy and resources, which can be a limiting factor.

Benefits of Plastic Manufacturing

Despite its limitations, plastic manufacturing provides many benefits. One of the most significant advantages of plastic is its versatility. It can be molded into almost any shape or form, making it ideal for a wide range of applications. Additionally, plastic is lightweight and durable, making it a cost-effective solution for many industries.

Applications Served Through Plastic Manufacturing

Plastic manufacturing has a vast range of applications, including:

Packaging Materials

Plastic packaging materials are widely used in various industries, including food and beverage, cosmetics, and pharmaceuticals. Plastic containers, bags, and films are preferred for their durability, flexibility, and ability to protect products from moisture, light, and air.

Construction Materials

Plastics are used in the construction industry due to their lightweight, durability, and ability to resist corrosion and weathering. They are used in pipes, insulation, roofing materials, siding, and flooring. Some of the most common plastics used in construction include PVC, polycarbonate, and acrylic.

Consumer Goods

Plastic is used in a variety of consumer goods, including toys, electronics, and household items. Many of these products require plastic due to its ability to be molded into various shapes and its lightweight and durable nature. Some popular consumer goods made from plastic include cell phones, laptops, toothbrushes, and toys.

Medical Devices

Plastic is widely used in the medical industry due to its sterile nature and ability to be molded into complex shapes. It is used to create devices such as syringes, IV bags, surgical instruments, and prosthetic limbs. Medical grade plastics must meet strict safety standards and are often designed to be resistant to bacteria and other harmful microorganisms.

Automotive Parts

Plastics are increasingly being used in the automotive industry due to their lightweight nature, durability, and ability to resist corrosion. They are used in various parts of vehicles, including dashboards, bumpers, and interior panels. Plastics can also help improve fuel efficiency by reducing the weight of the vehicle.

Agriculture

Plastic is used in agriculture in a variety of ways, including greenhouse covers, irrigation systems, and packaging materials for fruits and vegetables. Agricultural plastics are designed to withstand harsh weather conditions and are often treated to resist UV radiation.

Aerospace

Plastic is used in the aerospace industry due to its lightweight and durable nature. It is used in various parts of aircraft, including panels, insulation, and interior components. Plastics used in the aerospace industry must meet strict safety standards and are often designed to be resistant to high temperatures and other extreme conditions.

Sports Equipment

Plastic is used in various sports equipment, including helmets, balls, and protective gear. Plastics used in sports equipment must be durable, lightweight, and able to withstand high impacts.

Choosing the Right Plastic Manufacturer

To ensure you have the most constructive outcome when selecting a plastic manufacturer, it is important to compare several companies using our directory of plastic manufacturers. Each plastic manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each plastic manufacturer business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic manufacturers with the same form.

Die Cutting

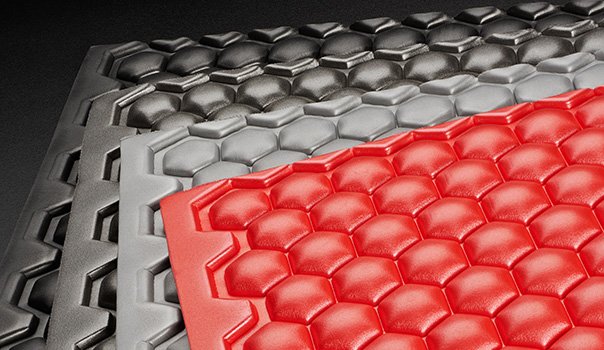

Die Cutting Foam Fab

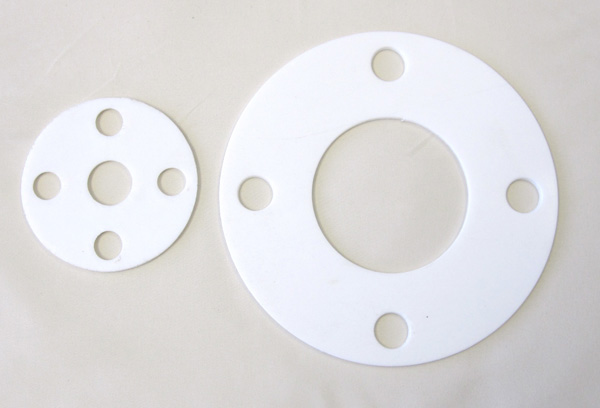

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services