Plastic cutters are used for commercial, industrial, and consumer applications. Manual plastic cutters are best for small-scale plastic-cutting operations, while automated plastic-cutting equipment works well for larger operations. Sheet and tube cutters are the two most popular kinds of plastic cutters. Read More…

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Plastic Cutter Companies

Sheet cutters are blades with handles made of plastic or rubber used to precisely trim plastic sheets. Plastic tube cutters create efficient, clean cuts in piping and pipefitting processes. Therefore, plastic tube cutters are preferable to other equipment like hacksaws.

Types of Plastic Cutting Methods

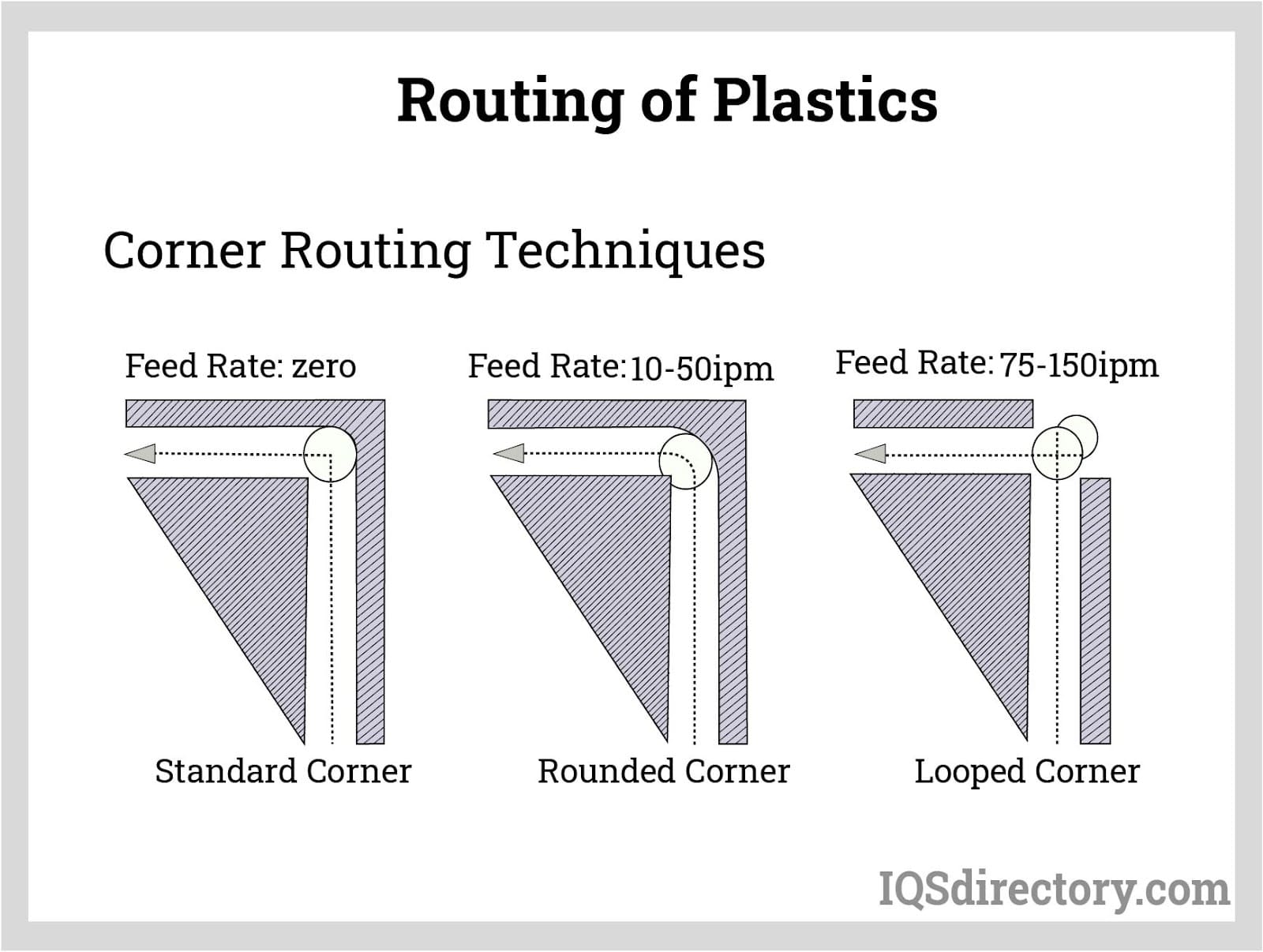

Routing and trimming are plastic cutting methods often used when machining plastic parts into finished goods. The secret to successfully machining plastic is to align the cutter design with the material's machining properties. Although the cutter/material properties are the main focus, other elements like coding and fixturing methods are equally important.

Routing

When routing polymers, it’s best to have fast feed rates with high-quality finishes. It can be difficult to cut plastic chips without rewelding them to the completed surface, especially when working with softer plastics. If the chips reweld to the surface, it could result in a subpar edge finish. The key to effective plastics machining is to avoid this rewelding and provide a fine edge finish while achieving high feed rates.

Keeping the chips cold is the key to avoiding rewelding with fast feeding rates. But this is only sometimes feasible due to programming restrictions. For example, when cutting radii and corners, most routers have acceleration, deceleration, and curve speed restrictions. When possible, avoid dead stops. The router may pause and loiter while changing directions when cutting outside corners.

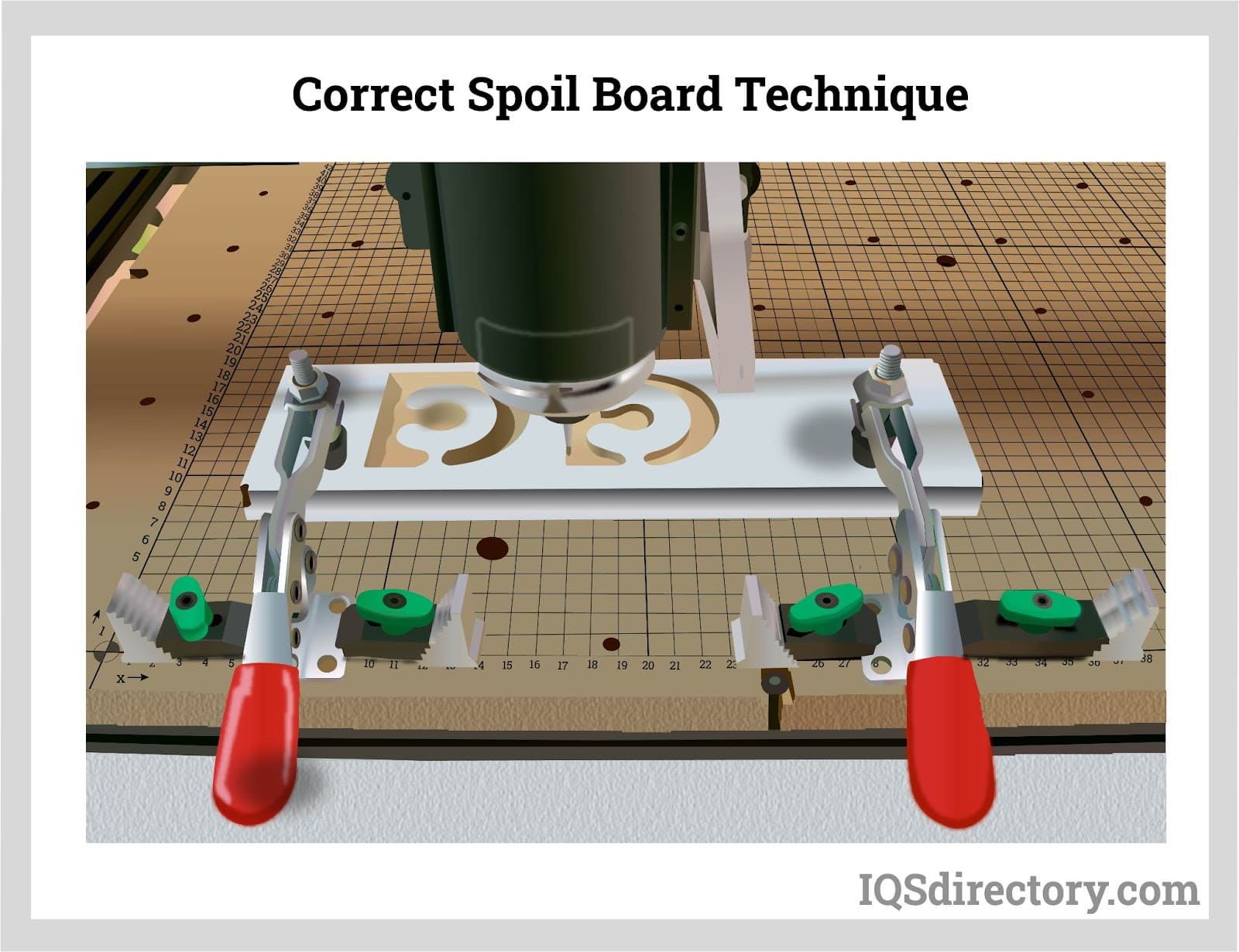

Correct Spoil Board Technique

Router bits may also linger in the opening dip of an inside cut. If the bit is not spiral or sheared, it will constantly re-contact the cut surface when boring, preventing the chips from being evacuated. There is a “ramp in” technique where one can gradually lower the bit as it moves forward to minimize leaving chips in the cut. Ramp programming to eliminate lingering might lengthen the routing path. Yet it can be economically viable because the tools won’t erode as quickly.

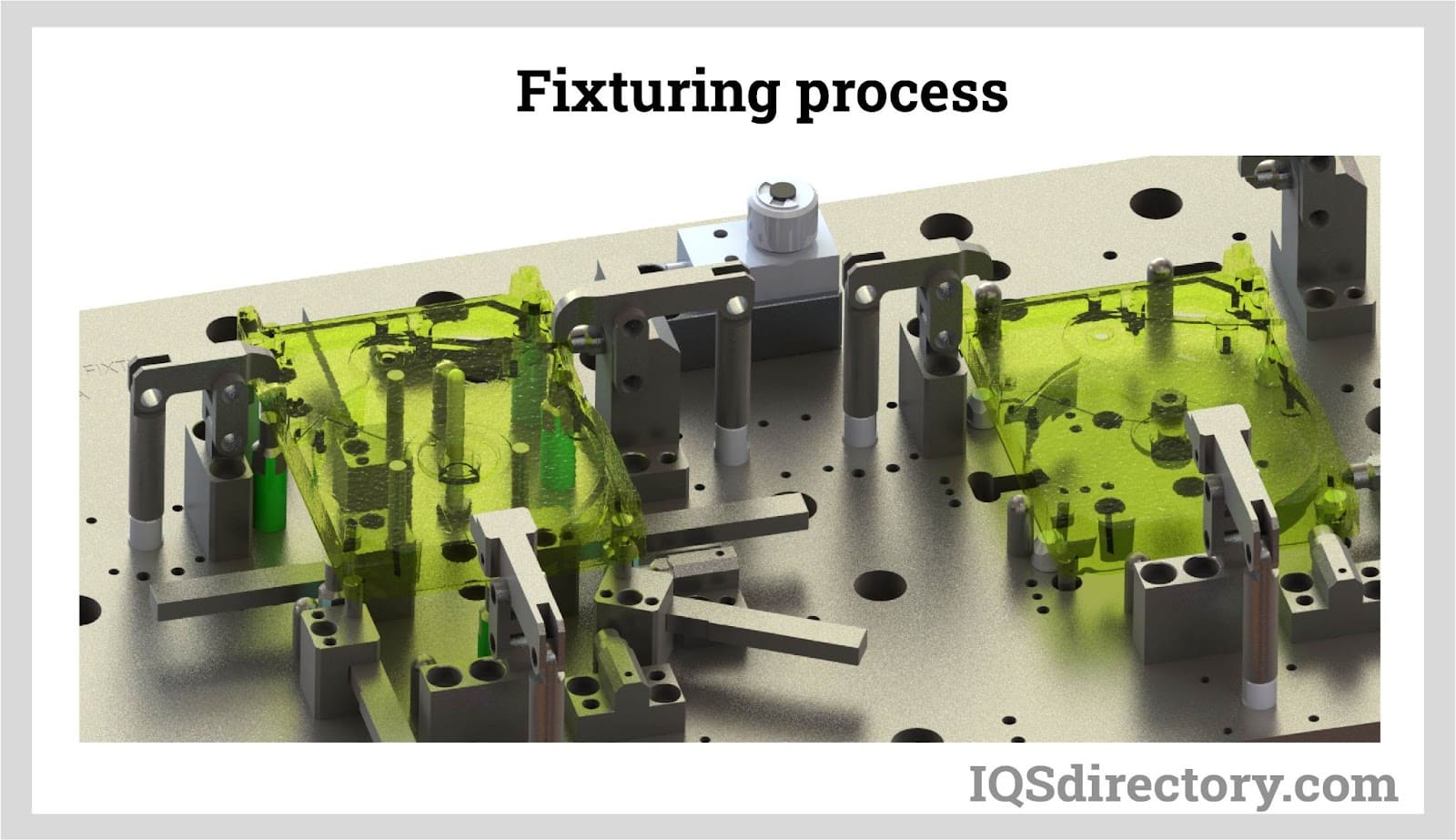

Fixturing

When cutting plastics, the fixturing needs to be dependable and sturdy. Any other outcome will eventually result in a subpar edge finish, a shortened tool life, or shattered tools. However, some particular methods and arrangements can result in an effective hold-down system.

Cutting Soft Plastics

When cutting soft plastics, the large chips produced during the machining are easily expelled from the router tip’s path. When routing soft plastics, manufacturers should remove long, curled chips from the material's face. These chips come loose easily, and edge burring or fuzzing is rare, if not nonexistent. As a result, manufacturers can cut soft plastics without worrying about abrasive or impact wear. The tool’s rake angle can be rather large, making it simple to separate a chip from the materials. As a result, the part moves less because of the cutting pressure and at quick feed rates.

Cutting Hard Plastics

When cutting hard plastics, the excess is typically tiny shards that mimic crystalline bits or dust. Instead of soft-plastic chips, hard-plastic waste is created by repeatedly breaking the underlying material into tiny, separate bits.

Choosing the Correct Plastic Cutter Manufacturer

To ensure the most productive outcome when purchasing plastic cutters from a plastic cutter manufacturer, it is important to compare several companies using our directory of plastic cutter manufacturers. Each plastic cutter manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each plastic cutter business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic cutter businesses with the same form.

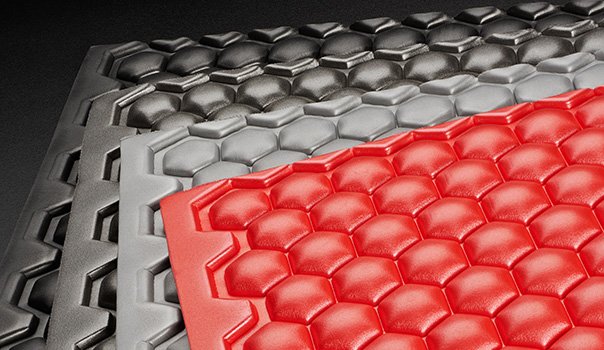

Die Cutting

Die Cutting Foam Fab

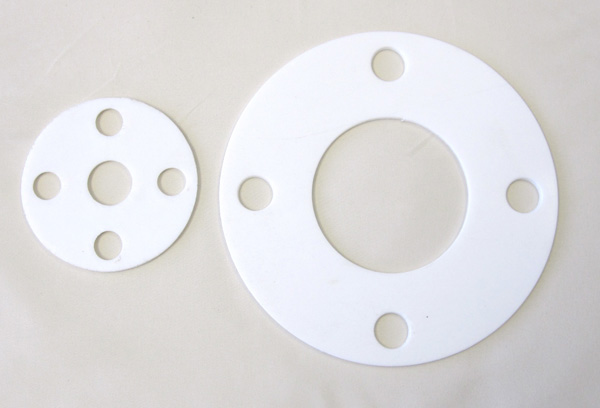

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services