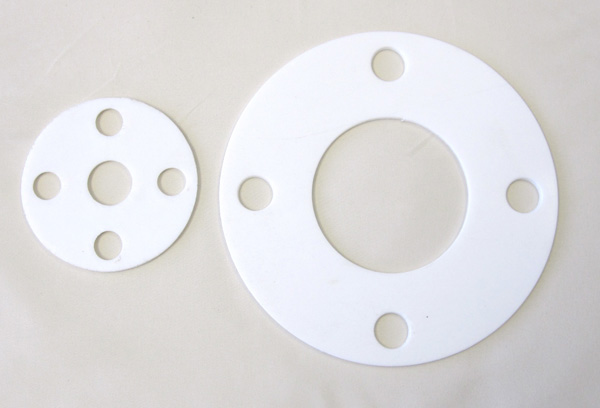

Plastic washers are discs with a center hole similar to metal washers and are used largely to spread the load of a fastener. Plastic washers prevent sparks due to their nonmetal nature, making the workplace safer and more dependable. In addition, plastic washers reduce maintenance downtime, which further streamlines manufacturing. Read More…

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Plastic Washer Companies

Plastic Washer Material

There are numerous materials available for plastic washers. The ideal material relies on the particular requirements of an application. Here are some typical materials of plastic washers:

Nylon Washers

Available in a variety of varieties, nylon is a highly elastic synthetic material that offers elasticity, resistance to abrasion, chemical inertness, and machinability. Due to its superior absorption and insulating qualities, this material is preferred for chemical and electrical applications. When weight is an issue, nylon washers offer a strong, portable alternative to metal washers.

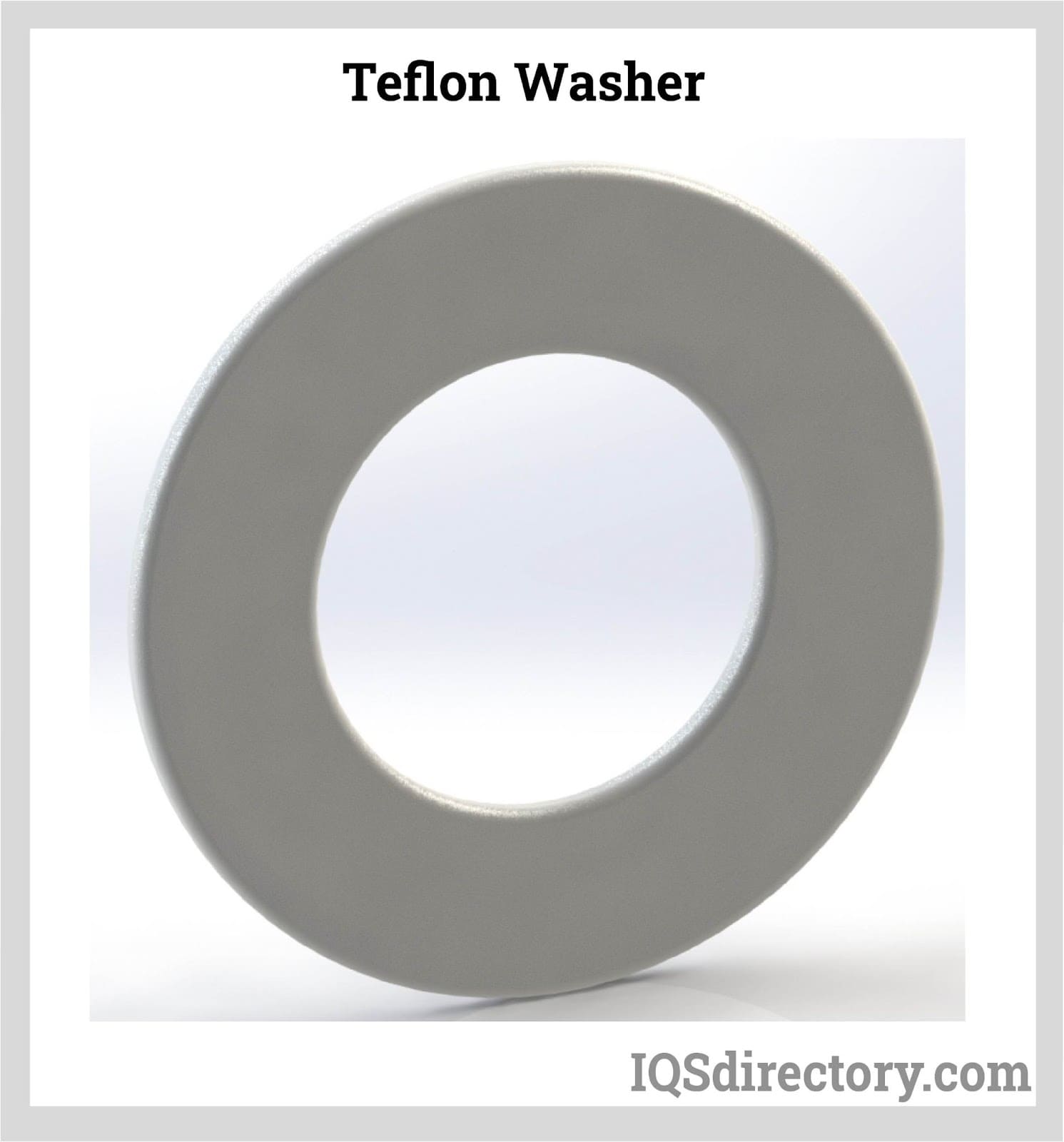

Teflon Washers

Also referred to as PTFE, Teflon is well known for having a very low friction coefficient and being impervious to water and oil. Teflon offers exceptionally high thermal and chemical resistance properties compared to other washer materials. These washers have low friction, making them perfect for plumbing, HVAC, and automotive applications.

Delrin Washers

Delrin is a proprietary homopolymer that delivers dimensional accuracy, hardness, and endurance in heavy-duty applications. In addition, it has a stable crystalline structure. Delrin washers are perfect for applications ranging from residential items to military equipment because the material is also impact- and temperature-resistant from -58 °F to 194 °F (-50 °C to 90 °C).

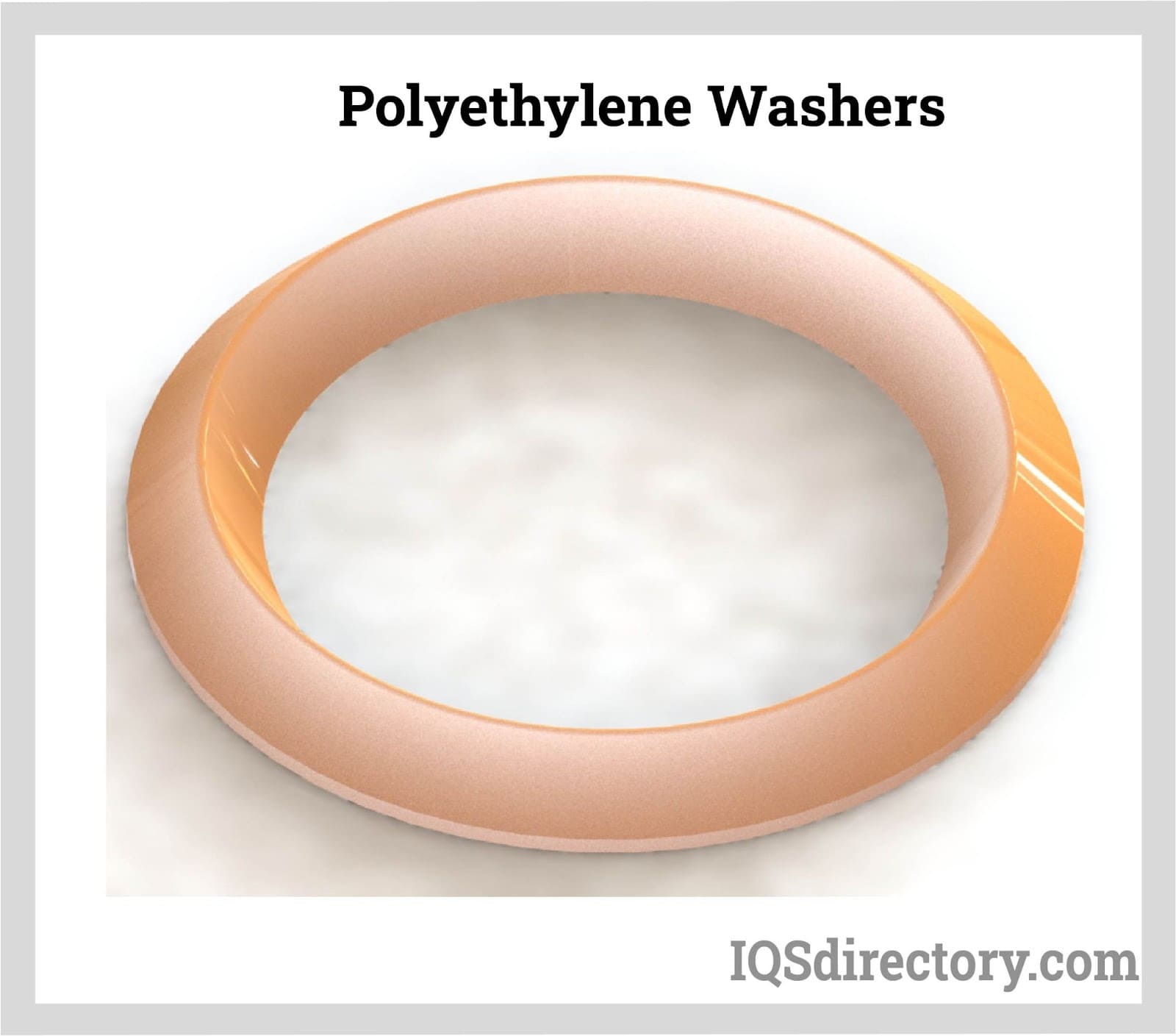

Polyethylene Plastic Washers

These are washers made of high-density polyethylene (HDPE) and low-density polyethylene (LDPE). The adaptability of LDPE washers makes them perfect for applications requiring water resistance in drains, water infrastructure, and liquid feeds. HDPE (high-density polyethylene) washers are more suitable for industrial and mechanical applications that value abrasion and crush resistance because they are tougher and less flexible.

Manufacturing Plastic Washers

Non-metallic stamping and injection molding are the two most widely used processes for obtaining and producing nylon washers. Non-metallic stamping has become a popular, low-cost substitute for injection molding because of its outstanding quality. The non-metallic stamping method may cut sheets of plastic and other thin non-metallic materials at extremely high rates using standard or high-speed punch presses and various dies.

Stamping Process

The stamping procedure produces massive volumes of plastic washers using a strong and high-production mechanical press. Washers can be produced in standard sizes or to special requirements. New combinations are less frequent since plastic stamping plants that manufacture washers frequently have a large library of old dies to choose from. Most washers are flat, and thick sheets of plastic are used in their construction.

A frame, bolster plate, and ram make up the three primary parts of a stamping press. Hundreds of washers can be made quickly and easily using this straightforward procedure. The finished frame is firmly clamped to the plate before the steel die is fastened to the ram. The heavy ram then exerts enormous power against the plastic sheet to carve out the washer pattern.

Injection Molding

Non-metallic stamping has become a popular, low-cost substitute for popular injection molding because of its outstanding quality. The non-metallic stamping method may slice strips of plastic and other light non-metallic materials at extremely high rates using standard or high-speed punching presses and various dies.

A plastic injection molding production technique is made for making big or medium-sized batches of identical items. It typically begins to have the edge over other approaches from just a few hundred pieces. Additionally, it is the technique that the plastics sector uses the most.

Advantages of Plastic Washers

- Impact Resistance: Impact-resistance glass and shields are made of materials like polycarbonate. Nylon or Polyurethane will isolate stress points and absorb impact shock to safeguard adjacent components. They can withstand the environment, particularly water.

- Fire Resistance: There are flame-safe and flame-retardant grades of several plastics. The price of previously required fire-suppression systems has decreased thanks to these goods, and in some circumstances, insurance rates in high-liability applications have also decreased. They are non-flammable and able to resist high temperatures.

- Vibration Resistance: Plastic washers can withstand vibration.

- Light Weight: Plastic washers are a logical substitute to reduce the weight of vehicles, aircraft, and other products.

- Insulating Properties: For electricity or temperature applications, non-metallic washers are a great alternative that doesn't throw off sparks.

- Food and Medical Usage: A wide variety of plastics, including those suitable for food applications, heart pump valves, and endoscopic equipment, have been certified for use in clinical uses.

- Low Cost: Plastic is less expensive than metal.

Choosing the Correct Plastic Washer Supplier

To ensure you have the most beneficial outcome when purchasing plastic washers from a plastic washer supplier, it is important to compare several companies using our directory of plastic washer suppliers. Each plastic washer supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic washer business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic washer suppliers with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services