Nylon washers are a crucial component in various industries, providing insulation and preventing damage caused by friction. They are made of high-quality nylon and come in a range of sizes, shapes, and thicknesses, depending on the application. In this article, we will discuss the various components of a nylon washer, its variations, the benefits of using nylon washers, some considerations regarding their use, and their numerous applications. Read More…

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Nylon Washer Companies

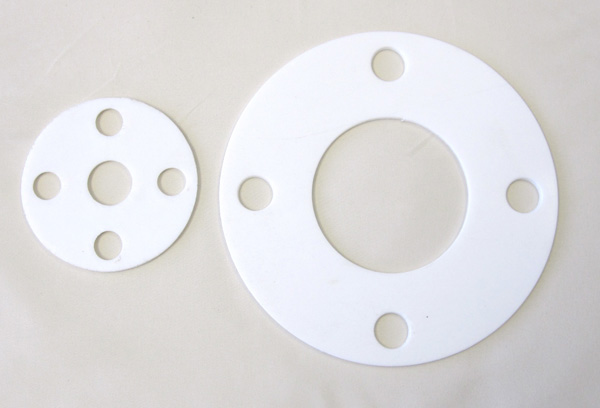

Design of a Nylon Washer

The material composition of a nylon washer is one of the most critical factors in its functionality. Nylon is the primary material used in making nylon washers due to its low coefficient of friction, high strength, and resistance to corrosion. The shape and size of a nylon washer can vary depending on the application, with a flat or shoulder design being the most common. The thickness of a nylon washer determines its load-bearing capacity, with thicker washers capable of withstanding more weight. The hardness of the washer is also important, with harder washers able to withstand more pressure.

Variations of Nylon Washers

Flat nylon washers are the most common type of nylon washer, with a flat surface and a hole in the middle for the bolt to pass through. Shoulder nylon washers are designed to provide additional support and prevent damage to the material being fastened. Nylon locking washers are designed to prevent the bolt from loosening due to vibration, ensuring a secure connection. Nylon spacers are used to separate two components, reducing friction and preventing damage caused by rubbing against each other. Custom nylon washers can be made to meet specific requirements, such as size, shape, or material composition.

Considerations Regarding Nylon Washers

Nylon washers have some characteristics that must be considered when selecting them for an application. They have temperature limitations and cannot withstand high temperatures or extreme cold. They also have chemical limitations and may not be suitable for use with some chemicals, depending on their composition. Wear and tear can also be a problem, and nylon washers may need to be replaced over time. Load-bearing capacity limitations must also be considered, as thicker washers may be required for heavier loads.

Benefits of Nylon Washers

Nylon washers offer several benefits, making them an excellent choice for various applications. They are corrosion-resistant, making them ideal for use in outdoor or marine environments. They have a low friction coefficient, reducing wear and tear on the components they are used with. Nylon washers are also lightweight, making them suitable for applications where weight is a concern. They are also electrically insulating, making them useful in electronic applications.

Applications of Nylon Washers

As a result of these beneficial qualities, nylon washers are used in a wide range of industries. Here is some more detailed information on the applications of nylon washers:

Automotive Industry

Nylon washers are commonly used in the automotive industry due to their resistance to wear and tear, high strength, and low coefficient of friction. They are used in engine components, suspensions, and brake systems to prevent damage and provide insulation.

Electronics Industry

In the electronics industry, nylon washers are used as spacers and insulation in electrical connections, printed circuit boards, and electronic devices. They provide electrical insulation, reducing the risk of short circuits and electrical damage to components.

Aerospace Industry

Nylon washers are also used in the aerospace industry due to their resistance to corrosion, low weight, and high strength. They are used in aircraft components, such as landing gear, engines, and control systems.

Medical Industry

In the medical industry, nylon washers are used in medical devices, such as surgical instruments and implants. They are biocompatible and can withstand sterilization, making them suitable for medical applications.

Construction and Home Improvement Industry

Nylon washers are used in construction and home improvement applications as spacers, insulation, and fasteners. They are used in plumbing, electrical systems, and general fastening to prevent damage and provide insulation.

Marine Industry

Nylon washers are used in the marine industry due to their resistance to corrosion, making them suitable for use in saltwater environments. They are used in boat components, such as engine mounts, steering systems, and rigging.

Sports Industry

Nylon washers are used in the sports industry to provide insulation and prevent damage to equipment. They are used in skateboards, roller skates, and snowboards to reduce friction and protect the components from wear and tear.

Food Industry

Nylon washers are used in the food industry due to their resistance to chemicals and ability to withstand high temperatures. They are used in food processing equipment, such as mixers and conveyors, to prevent contamination and provide insulation.

Choosing the Right Nylon Washer Supplier

To ensure you have the most productive outcome when purchasing nylon washers from a nylon washer supplier, it is important to compare several companies using our directory of nylon washer suppliers. Each nylon washer supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each nylon supplier business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple nylon washer companies with the same form.

Die Cutting

Die Cutting Foam Fab

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services