Parker Plastics

Parker PlasticsRequest A Quote

London, ONPark Plastic Products is your liquid storage and transport experts. As a custom fabricator of polypropylene and co-polymer tanks, we are the superior choice for chemical and high temperature liquid storage. Founded by Eugene K. Park in 1972, Park Plastic Products was one of the first distributors of plastic storage tanks in the country. Then known as E.K. Park, Inc. with only one size of tank, we distributed tanks across the east and Midwest as we developed the product line throughout the decade. Now offering a complete line of rotationally molded tanks, Park Plastic Products has the perfect solution for you. Our product line includes dip tanks, vertical tanks, containment tanks for hazardous chemicals, cone bottom tanks , horizontal legs tanks, air purification tanks and custom rolled polypropylene tanks. All our tanks can be built to your size and specifications. No matter your application, we are sure to have the right product for you. We specialize in custom plastic fabrication. We also offer heat traced and insulated tanks. They are the ideal choice for when you need consistent temperatures. Since our inception our most important commitment has been to our customers. Our pride lies within our excellent service, cost effective prices, and unmatched quality. Your satisfaction is our top priority. Our state of the art facility allows us to custom build tanks with precision. Throughout the manufacturing process, we test each tank to ensure premium quality. We serve customers nationwide.

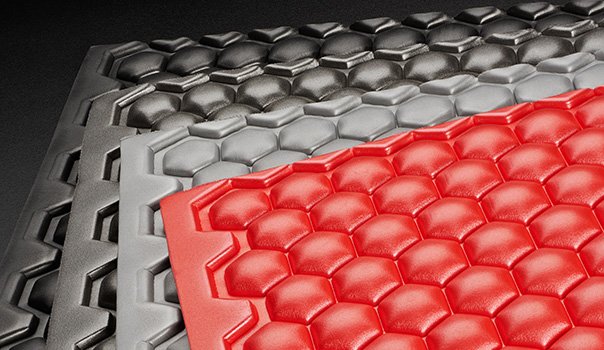

Die Cutting

Die Cutting Foam Fab

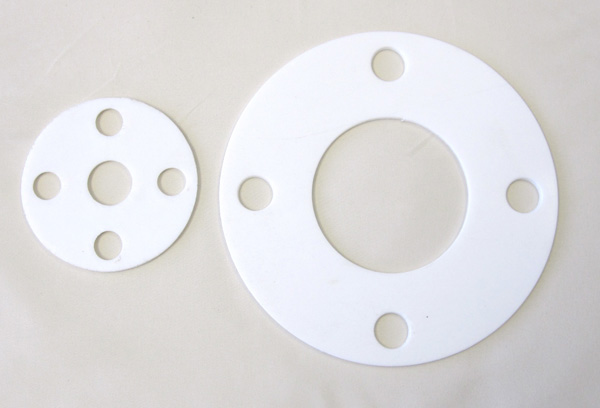

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services